Machine Screw Thread Applications for Product Developers

In part one of this series, we looked at the fundamentals of machine screw thread design. This information is invaluable for engineers and product designers, and it’s also a fascinating look at one of history’s fundamental machine tools. Now that we know something about threads and screws in a general sense, it’s time to apply that information to specific applications. The Weakest Link Screws, threaded fittings, […]

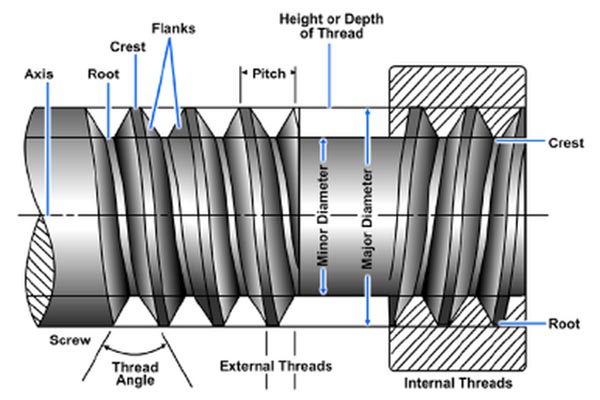

What Every Engineer Needs to Know About Machine Screw Thread Design

Machine screw threads, along with many other kinds of threaded fittings, are used around us every day in millions of applications. In fact, they’re so ubiquitous that they largely go unnoticed by most of us, and to the inexperienced eye they all look and perform pretty much the same. In fact, screw threads are surprisingly […]

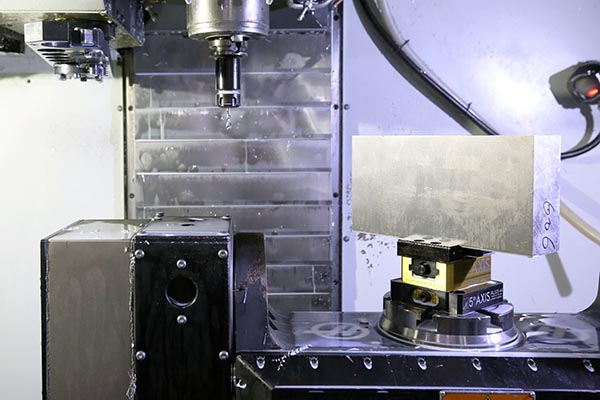

What is the Difference between 3, 4 and 5-axis CNC Machining?

Modern CNC milling machines are amazing tools, capable of making prototypes and production parts quickly and reliably. To do this they must be able to move along several axes of travel while maintaining dimensional accuracy. CNC mills are therefore categorized by the number of axes along which they operate, with 3, 4 and 5-axis mills […]

Top 7 Advantages to Using CNC Machining for Rapid Prototyping

Rapid prototyping means building a physical model of a new product design as quickly and as economically as possible. Some prototypes will be used merely as cosmetic mock-ups or scale models, while others must meet more demanding performance criteria. Prototypes are used for testing, design iteration and to improve overall performance through gradual refinements. For […]

Metal 3D Printing – How Does it Work?

What Is Metal 3D Printing? Metal 3D printing is a revolutionary technology that produces impossible-to-make parts directly from CAD data. Advantages to this process include the ability to produce strong, complex geometries, internal lattice structures, conformal cooling channels and other features that cannot be made with traditional machining. Parts can be made quickly with a […]

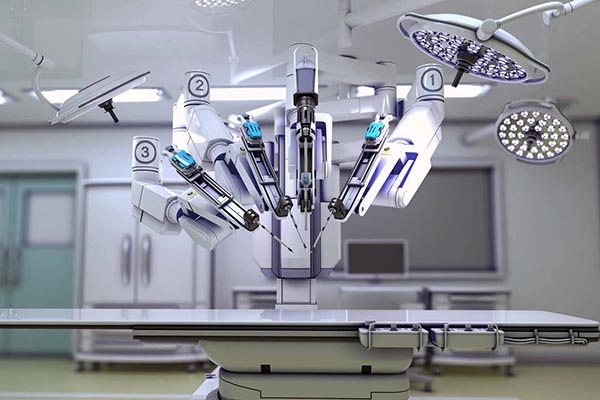

CNC Medical Machining: Benefits of CNC Machining for Medical Industry Products and Parts

CNC machining, in its many forms, is one of the most versatile of all conventional manufacturing processes. The versatility of cnc machining extends to the types of parts that can be made, the material from which they are made, and the volumes produced. Using conventional CNC milling and turning, parts can be made for medical […]

Portuguese

Portuguese French

French