Blog

Star Rapid’s blog aims to share our hard earned knowledge on manufacturing and product development. We hope these articles help you to optimize your product design and better understand the world of rapid prototyping, rapid tooling, 3D printing and low-volume manufacturing.

8 Things You Need to Know About Anodizing Aluminum

Anodizing is a method for changing the surface chemistry of metals and other substrates. It protects against corrosion, enhances aesthetic qualities, resists scratching and is one of the most durable surface finishes available. Let’s take aluminum as an example to see how this process cleverly exploits oxidation for a result that’s both decorative and functional.

3DPrinting.com: “3D Printing Rekindles The Spirit of Invention”

Star Rapid’s CEO Jon Ross offers some insights on 3D printing and its ability to encourage people of all ages to get involved in the joy of making things again.

Gordon Styles featured in Assembly Magazine: 3D Printing In Metal

2017 has seen a continuation of the trend in adopting 3D metal printing for demanding industrial applications. This has been especially true in the fields of aerospace, automotive and medical applications, but will undoubtedly disrupt other sectors as this transformative technology becomes more mature and better understood by product designers, engineers and manufacturers.

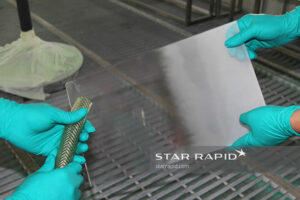

What is Vapor Polishing? Vapor Polishing Explained

Vapor polishing is a finishing service commonly used to achieve high levels of transparency in plastic, like when plastic is used to make a lightweight optical quality lens. In situations like these, vapor polishing is one of the best and fastest ways to achieve optimal transparency. In cases where absolute transparency isn’t

Choose The Right Plastic For Your Next Project

With thousands of plastics on the market, it can be a daunting task to decide which type is the best for your next rapid prototyping or low-volume manufacturing project. When choosing which plastic to use, there are going to be trade-offs between cost, moldability, surface finish, durability, strength and many others. The

Encouraging Young Graduates To Get Excited About Manufacturing

On Thursday July 6th, a group of 7 recent graduates from the Zhongshan Polytechnic University came to visit Star Rapid to understand more about manufacturing in a high-tech environment.