Polyurethane Vacuum Casting

From 1 to 50+ Parts Global Delivery

Vacuum Casting Service

We offer a complete turnkey solution for creating master patterns and cast copies based on your CAD designs. We not only make high-quality molds but we also offer a full line of finishing services including painting, sanding, pad printing and more. We’ll help you create parts for showroom quality display models, engineering test samples, crowdfunding campaigns and more.

Do you need production quality plastic prototypes fast? Polyurethane vacuum casting may be the ideal solution for you. Star Rapid’s vacuum casting service is renowned for producing showroom quality display models, engineering samples, crowdfunding prototypes and more. And of course all of your parts are expertly finished with professional painting, printing and machining.

What Is Vacuum Casting?

Polyurethane vacuum casting is a specialized technique for making high-fidelity copies of master patterns using inexpensive silicone molds and pourable casting resins. Copies made in this way demonstrate the same quality as plastic injection molded parts while taking only a fraction of the time and expense to produce.

Advantages Of Vacuum Casting

- Low cost for molds

- Molds can be made in a few days

- Many types of polyurethane resins are available for casting, including overmolding

- Cast copies are highly accurate with excellent surface texture

- Molds are durable for 20 or more copies

- Perfect for engineering models, samples, rapid prototypes, bridge to production

Enquire About Vacuum Casting

Do not hesitate to contact us for more information about vacuum casting. Your customer support partner

will contact you directly to answer any questions you may have.

When to Use Vacuum Casting?

Product developers turn to vacuum casting when they need only a small volume, between 10 to 20 pieces, of production quality plastic parts while avoiding the long lead time and financial commitment of making plastic injection mold tools.

These parts are used for prototypes and display models, for crowdfunding and trade show campaigns, to test a new design for fit and function, and as a bridge to larger production volumes. Vacuum casting can also be used for end-use parts in some applications, since the pourable casting resin effectively mimics the performance of ABS, Nylon, PP, acrylic and soft TPE rubber.

Materials

The vacuum casting materials that we use at Star Rapid are two-part resins that we mix just before pouring them into the silicone mold. These resins are analogs of common plastic injection molding material and they offer comparable appearance and performance.

We can duplicate polypropylene, ABS, nylon, acrylic, and various hardnesses of soft elastomer. We can also add glass fibers to increase the stiffness of ABS and nylon for even more design options.

Why Choose us

Why Choose Star Rapid for Vacuum Casting Services?

When it comes to vacuum casting, there are a number of manufacturers to choose from. Choosing the right one is essential for getting exactly the results you expect. Here are several reasons to choose Star Rapid for your vacuum casting needs.

Quality shouldn’t have to come at the expense of speed, and vice versa. At Star Rapid, we combine our extensive experience with the industry’s latest tools and technologies to deliver high-quality vacuum casting services on short timelines (typically in 7 to 14 days).

Vacuum casting isn’t all we do. As your one-stop production shop, we also offer a wide range of complementary finishing services to help your product come to life. Our finishing services include machining, media blasting, printing, painting and more.

Your needs are unique — and you don’t want to pay for more than you need. That’s why we never require a minimum order volume or minimum dollar value for our vacuum casting services. We also use state-of-the-art AI quotation algorithms for fast, accurate quotes in 24 hours or fewer for nearly all projects.

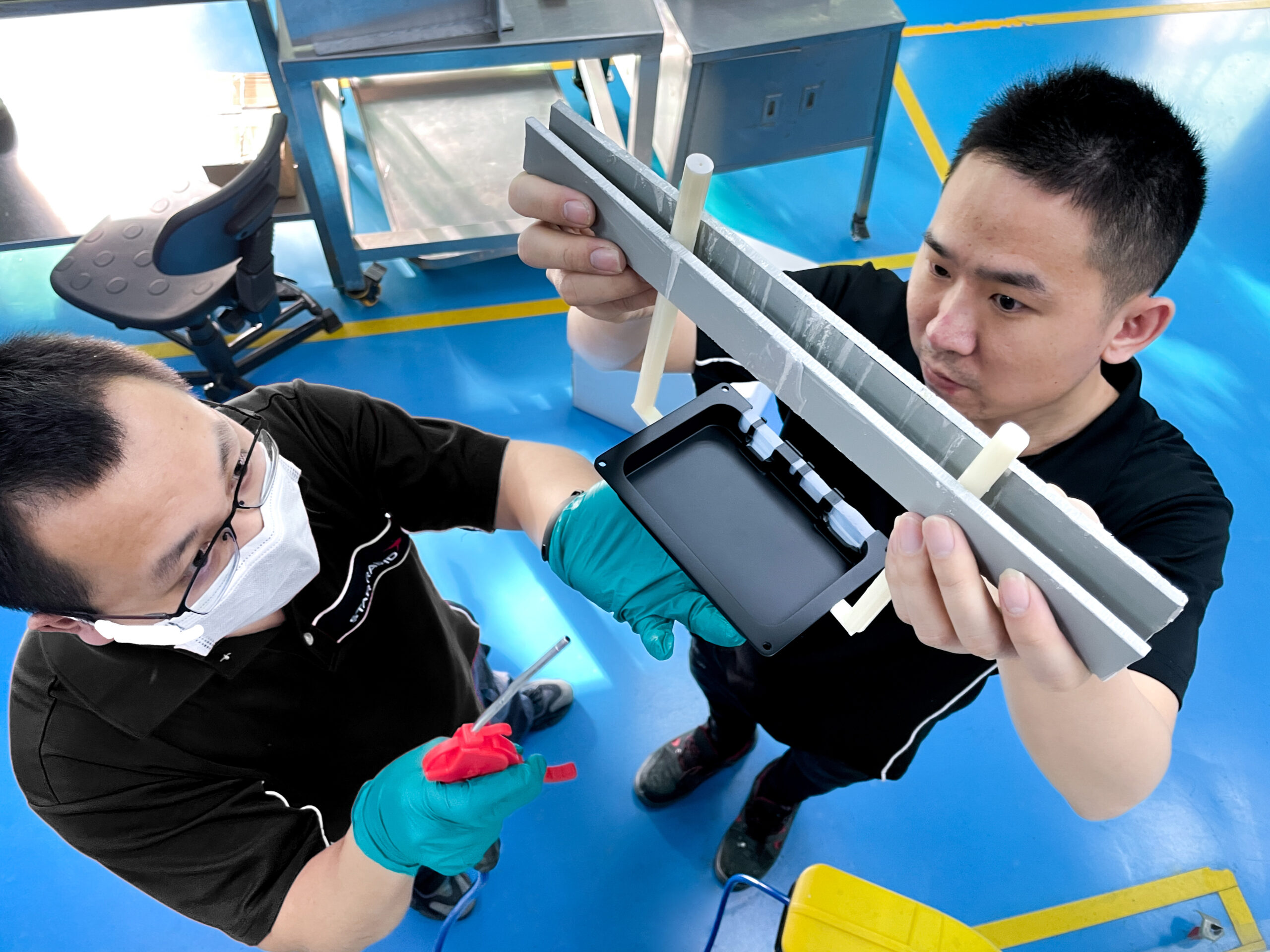

As vacuum casting is often used for prototyping, we know that many of the products we work on haven’t reached their final design. To help them get there, we provide detailed design for manufacturing support to our clients. (We can even make your patterns for you.) We also offer detailed video files showing all production steps for clients who can’t visit us in person.

To ensure exceptional product quality from the get-go, we only use the highest quality resins from the best international brands.

Enquire About Vacuum Casting

Do not hesitate to contact us for more information about vacuum casting. Your customer support partner

will contact you directly to answer any questions you may have.

Vacuum Casting: Further Reading

Six Reasons To Use Vacuum Casting For Medical Products

Virtually all new products intended for the medical industry start out as prototypes. Prototypes are

Overmolding for Vacuum Casting Prototypes

Polyurethane vacuum casting is a great way to make quick-turnaround rapid prototypes. Solid master patterns

Benefits of Vacuum Casting for Rapid Prototypes

If you’re wondering what the most cost-effective way to make any prototype is, it may

Who we are

Vacuum Casting Process

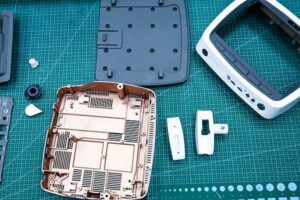

There are three steps to making polyurethane vacuum cast parts: making the master pattern, making molds and casting the parts.

Patterns are 3D solids of your CAD designs. They are usually made by CNC machining or with 3D plastic printing such as SLA/SLS. You can supply your own patterns or we can make them for you. Patterns need to be able to withstand heating to 40°C.

A master pattern can be any physical solid of your design. They are often made either by CNC machining or some form of 3D printing such as SLA. Note, however, that a pattern made from 3D printing will not be quite the same as the CNC counterpart, since the later process uses round cutting tools that cannot make very tight radius corners.

Casting molds are made from liquid silicone. This silicone is poured around the master pattern inside of a casting box, and then allowed to cure in an oven for 16 hours. Once dried, the mold is cut open and the master removed, leaving behind an empty cavity in the exact negative shape of the original.

First the pattern must be carefully prepared, and that means sanding and sealing the surface with primer. Once it’s ready, it’s placed into a casting box and liquid silicone is poured around it. Depending on the size of the part, it can take 12~24 hours to fully cure inside of an oven. Once dried, the mold is cut open and the master removed, leaving behind an empty cavity in the exact negative shape of the original.

Your choice of casting resins can now be poured into the empty cavity to create a highly accurate copy of the original. It’s even possible to overmold with two or more materials. Silicone molds are typically good for 20 or so copies of the master pattern.

Vacuum Casting Tolerances

The finished dimensions of vacuum cast parts are dependent on the accuracy of the master pattern, the part’s geometry and the type of casting material used. Generally a shrinkage rate of 0.15% is to be expected.

See Our Past Projects

The latest and greatest post and projects from Star Rapid

The ProEx Telehealth Hub by VisionFlex is a great example of a successful collaboration between product developer and manufacturer. We worked closely with VisionFlex to optimize their design in order to produce a showroom-worthy prototype. Learn how we did it in this case study. Read more…

SKIIN is an innovative line of smart clothing developed by the Canadian company Myant. Small, light and sophisticated sensors are housed in discrete cases, made with the help of Star Rapid’s vacuum casting service. See how we helped them bring SKIIN to life. Read more…

Common Questions

Star Rapid Vacuum Casting Service FAQ

Want to learn more?

Our vacuum casting service is noted for its exceptional quality and speed. Our skilled technicians combine decades of experience with the latest technologies to produce exceptional prototypes and engineering models quickly. We can also further enhance your parts with a suite of finishing services including machining, media blasting, printing, painting and more.

Yes. To supplement our vacuum casting services, we offer an expanded service geared for design-for-manufacturing support. While we once reserved this service only for approved orders, we now provide it to all incoming RFQs. We also offer light assembly services to meet your needs.

To ensure the highest standard of quality for all of your finished parts, our team adheres to a strict quality control process. This starts with the verification and testing of all materials. During production, we meticulously control temperature, humidity and other processing conditions to maintain the highest degree of consistency in your parts.

We make it easy to get a fast quotation. Simply upload your CAD files and product details and we’ll send you a free quotation within 24 hrs. or less.

There are some limitations to the vacuum casting process. Developers need to use good design practices to ensure enough draft so the part can be released. For the same reason, avoid undercuts, deep ribs, bosses and other features that will destroy the relatively soft silicone mold when it opens.

When our technicians cut the mold open to remove the master pattern, they make a sawtooth pattern on the cutline that acts like a key. This helps the mold to be resealed in the correct orientation for pouring resin. The mold merely needs to be taped and stapled shut to avoid any leakage during the pour.

Request Your Free Vacuum Casting Quote Today

After receiving your drawings, our engineers will analyze your custom vacuum casting parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.