World-Class Injection Molding Services

Small and large scale injection molding Request an injection molding quote today

Injection Molding

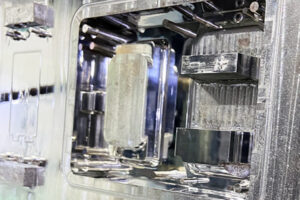

Star Rapid is a world-class provider of advanced injection molding services. We offer a complete manufacturing solution that covers every aspect of positive material identification, tool making, part fabrication, finishing, and final inspection. Our international team of manufacturing experts is committed to providing you with the highest level of professional support for injection molding services of any size or complexity. We offer three tiers of injection molding services to ensure that you get precisely the solution that’s best for your intended volume, production time and budget.

Star Rapid Provides Injection Molding Services

Rapid tooling is ideal for quickly making smaller volumes of parts that are suitable for engineering testing, new product development, proof-of-concept, and as a bridge to mass production. Learn more about our rapid tool making and injection molding services.

Micro molding is a specialized service for making unlimited volumes of parts on the small scale. For tomorrow’s advanced micro mechanical devices, micro molding can save both time and money. Learn more about micro injection molding services at Star Rapid.

Production tooling is for customers who need high volumes of identical plastic parts and enclosures. Production tools require careful engineering, high performance tool steels, and exacting process control to achieve repeatable results.

Plastic Injection Molding

Injection Molding Resources

Latest news and resources on injecting molding services

Understanding multi-cavity designs for injection molding efficiency

There are three general categories of plastic injection mold tools that product designers can consider when making finished parts. They

The Top 4 Surface Treatments for Production Tooling

TiN coating on mold tool. Image courtesy of prirev.com.All manufacturing tools are subject to incredibly harsh working conditions and must

The 5 Most Common Methods for Applying Textures to Injection Molding Tools

Surface textures and patterns applied to plastic injection molded parts are becoming more sophisticated and complex. These advancements are exciting

Why Choose us

Why Choose Star Rapid for Injection Molding

The finest production mold tools start with quality raw materials, strict process control, and expert toolmakers. Only a supplier with years of experience supporting Fortune 500 companies can ensure repeatable results for your production tooling needs. Here are some of the advantages the Star Rapid offers for high-volume production tool making and injection molding services.

We offer more than just tool making and molding services. Our complete package includes every manufacturing process you need for a total product development solution.

Thousands of companies of every size from around the globe have chosen to work with Star Rapid to help them develop new injection mold tools and finished parts. Your success is the foundation of our reputation.

Your regulatory compliance and your peace of mind are assured with our industry-leading positive material identification department. People trust Star Rapid when the job absolutely must be right.

A comprehensive design for manufacturing review comes with every tool and product design project. You’ll receive superior results while saving time and money.

We support your development goals by having no minimum order volumes or value for our injection molding production. In addition, we have a proprietary AI quoting algorithm that provides fast, accurate, and transparent pricing on every project, every time.

Advantages Of Injection Molding

Injection molding services from Star Rapid offer you many advantages. It’s the most stable and reliable way to make unlimited volumes of end-use plastic parts to suit virtually any application in any industry. In addition, engineering resins can replace metal parts in many cases, which reduces weight and saves cost.

Thousands of resins to choose from

Highly automated for efficiency

Stable and repeatable

Excellent surface quality

Overmolding for more design options

Multi-cavity and family tools

Star Rapid

Injection Molding Projects

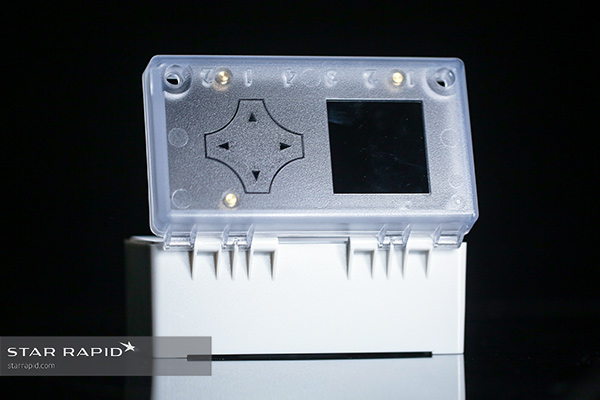

Star Rapid worked with Powelectrics to make the enclosure for their Metron4. Read how we made a case that’s strong and weatherproof for the toughest field conditions.

Marco Beverage designed a high-end reservoir for their coffee making system. Learn how we helped them to bring this product to life with careful tool engineering.

Request Your Free Injection Molding Quote Today

After receiving your drawings, our engineers will analyze your custom injection molding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.