Blog

Star Rapid’s blog aims to share our hard earned knowledge on manufacturing and product development. We hope these articles help you to optimize your product design and better understand the world of rapid prototyping, rapid tooling, 3D printing and low-volume manufacturing.

We’re Expanding! New Equipment and Software.

The recent rebranding of Star Prototype to Star Rapid is much more than a name change and a fresh coat of paint. Our rebranding also coincides with an expansion of our 60,000 square foot facility and a significant investment of more than US $2.5 million in cutting-edge manufacturing equipment and management

Why Did We Rebrand? An Interview With Gordon Styles

We have just rebranded to Star Rapid, a change that coincides with the expansion of our facilities. Find out what Star’s founder and president, Gordon Styles, has to say about why we changed our name to Star Rapid. Q: After ten+ years of successful business as Star Prototype, why is the name changing, and why now?

Is SLA The Right 3D Printing Solution For You?

3D printing in plastic began more than 35 years ago with the invention of stereolithography (SLA). Although there have been many developments in additive manufacturing since then, SLA is still a popular process for rapid prototyping. First let’s take a look at how the technology works, and then see why it

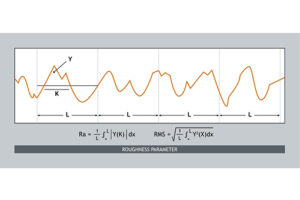

Understanding Surface Roughness for Product Development

Surface roughness is often described by the term Ra but many of our clients are unsure about what this means, how it’s measured and why it’s important to their product’s designs. So here we’d like to remove any mystery so you’re better able to specify exactly the type of surface

What are the Top Passivation Techniques?

What Does Passivation Mean? Passivation means to alter the chemical structure of a metal at or just below the surface, so that it’s more stable and doesn’t want to react with other elements in an undesirable way. There are several different manufacturing processes that we routinely use to passivate the

How To Control Weld Lines In Plastic Injected Molded Parts

Plastic injection moulding is the industry’s most common way to manufacture parts. This production method is particularly popular when manufacturing in large quantities. Weld lines are a common imperfection to be found in most plastic injected molded parts. They are the result of fundamental physical effects taking place inside of the