A Complete Guide to Overmolding vs Insert Molding

In this article, we discuss insert molding and overmolding, the advantages of each, and the applications they’re best suited for. We hope these manufacturing insights, along with useful design tips, will help you get great results on your next plastic injection molding project. Navigate to these sections in the article: What is Overmolding? What is […]

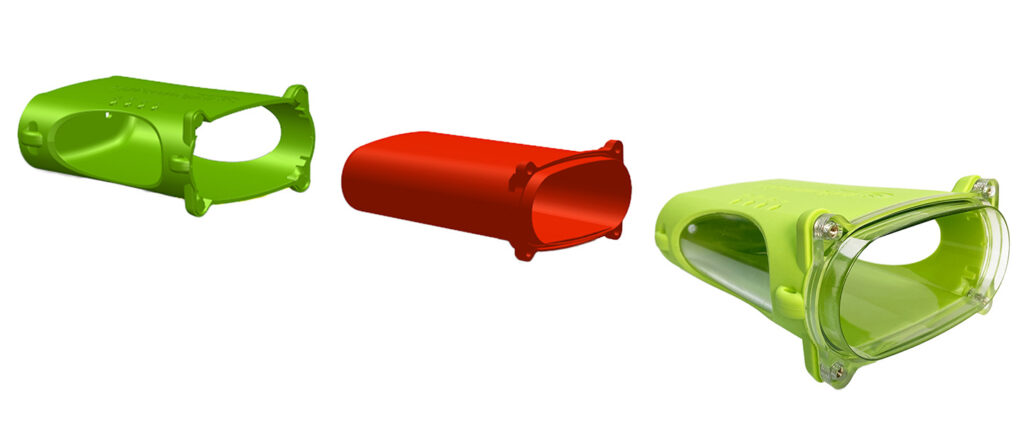

Rapid Prototyping With Polyurethane Vacuum Casting

Many plastic injection molding projects start off by first making a series of rapid prototypes. These are used to further refine the look and feel of the part, to test its functionality, and to improve the design before investing in steel injection mold tools. In this video, Gordon Styles explains why rapid prototyping using the […]

Manufacturing Cycle Times and How To Improve Them

Every business has a vested interest in carefully monitoring its productivity, especially in a manufacturing environment where repetitive tasks can be standardized and optimized. The most common metrics used for this purpose are manufacturing cycle times, lead times, and takt times. Progressive companies try to control these factors in order to save money, conserve valuable […]

Color Consistency in Plastic Injection Molding

It’s a big challenge to achieve color consistency for large production runs of plastic injection molded parts. To ensure consistency when molding colors, it’s essential that you have careful process control at every step. It’s important to note that plastic color is highly subjective – subjective in how you see and interpret plastic color. It […]

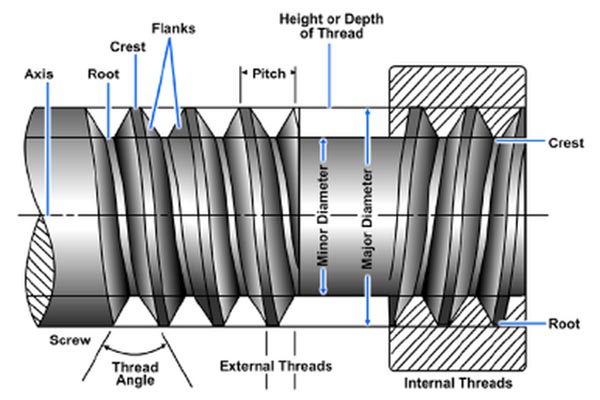

What Every Engineer Needs to Know About Machine Screw Thread Design

Machine screw threads, along with many other kinds of threaded fittings, are used around us every day in millions of applications. In fact, they’re so ubiquitous that they largely go unnoticed by most of us, and to the inexperienced eye they all look and perform pretty much the same. In fact, screw threads are surprisingly […]

Five Rapid Prototyping Solutions For Great Results

Ever since people started making stuff – and then tried to make new and improved stuff – there’s been a need for prototypes. They’re used for design evaluation, testing, certification, proof-of-concept, crowdfunding campaigns and as bridges to full production. If you need high-quality rapid prototypes, may we suggest you consider these 5 well-established and mature […]

Portuguese

Portuguese French

French CHINESE (中文)

CHINESE (中文) German

German