How To Talk About Surface Texture Like A Pro

As a product designer you know that your choice of a surface texture goes a long way towards determining how your product looks, feels and performs. However, you may not realize that there’s a specialized vocabulary used by manufacturers when they make and describe surface textures. If you become familiar with these terms and how […]

Anodized Aluminum Colors: Understanding Color Matching

A Walkthrough of the Aluminum Anodizing and Color Matching Process Anodizing is a great way to put an attractive and physically durable finish on aluminum parts. Anodizing improves corrosion resistance, surface hardness, prevents scratching and is an ideal foundation for painting, glue or powder coating. There are many challenges when trying to match colors on […]

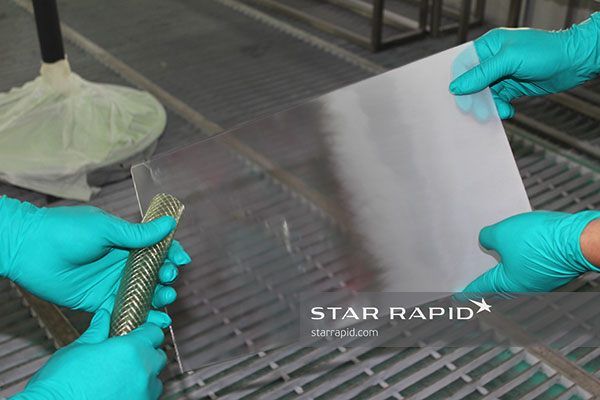

What Makes a Great Paint Job

When people think of paint, they tend to think of it in a general sense. They often picture a smooth liquid substance that—once applied to a surface—can bring walls, buildings, and furniture to life. The definition doesn’t do justice to the sophisticated chemistry underlying modern coating technology. At Star Rapid, we use a variety of […]

Plastic Injection Molding Surface Finish: Making and Measuring Textures For Injection Molding

All plastic injection molded parts have a surface texture created by the tools that made them. To get the surface finish and texture that you want from injection molding, it’s important for you to learn how we make and measure such finishes in our inspection department. At Star Rapid, we follow the finishing standards of […]

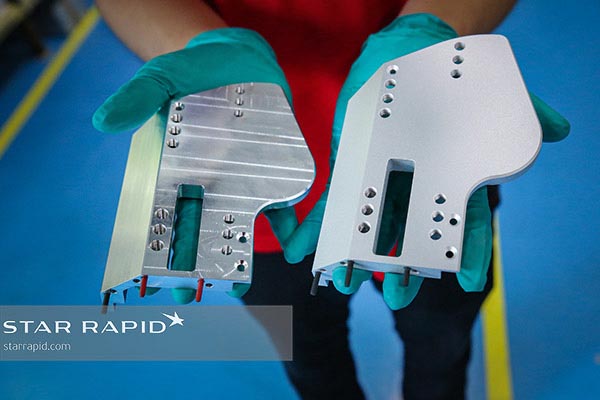

8 Things You Need to Know About Anodizing Aluminum

Anodizing is a method for changing the surface chemistry of metals and other substrates. It protects against corrosion, enhances aesthetic qualities, resists scratching and is one of the most durable surface finishes available. Let’s take aluminum as an example to see how this process cleverly exploits oxidation for a result that’s both decorative and functional.

What is Vapor Polishing? Vapor Polishing Explained

Vapor polishing is a finishing service commonly used to achieve high levels of transparency in plastic, like when plastic is used to make a lightweight optical quality lens. In situations like these, vapor polishing is one of the best and fastest ways to achieve optimal transparency. In cases where absolute transparency isn’t necessary, such as when making clear […]

Portuguese

Portuguese French

French CHINESE (中文)

CHINESE (中文) German

German