What Is A Coordinate Measuring Machine Used For?

One of the essential workhorses for product verification is our coordinate measuring machine. We use it every day to qualify rapid prototypes and production parts that have complex geometries with tight tolerances. Learn more about how this versatile machine is one more way we ensure every part we make meets and exceeds your expectations. CMM […]

Exoskeletons and Assistive Devices To Enhance Human Potential

Many businesses and organizations, including manufacturers, are now exploring advanced powered and unpowered exoskeletons to enhance mobility, increase strength and protect against fatigue and injury in a variety of conditions. We think this will be great for productivity, but it also represents a boon for the elderly and the disabled who need additional support to […]

The Micrometer, Its Parts, and Why It’s Essential for Making Quality Parts

The micrometer helped to create accuracy in modern manufacturing. What is a micrometer? A micrometer is a sensitive tool for making accurate measurements of linear dimensions. It’s one of the most important measuring instruments ever made. It has a rigid C-shaped frame. One side has an anvil that is fixed, and on the other side […]

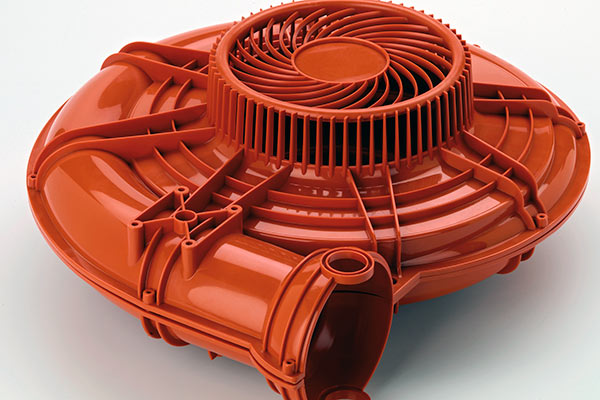

How Pressure Affects Your Plastic Injection Molded Parts

There are many forms of pressure involved in making a plastic injection molded part. We’ve explained the importance of clamping pressure before, so now let’s look at three others: injection, holding, and back pressure. Why is this important to you? Because balancing these forces correctly is one of the keys to making consistently good parts. […]

How Clamping Pressure Impacts Your Injected Molded Parts

Pim for web Getting the best results from plastic injection molding requires that the process control engineer carefully balances several related variables when setting up the machine. One of these variables is clamping pressure. What is Clamping Pressure? Clamping pressure is a measurement of the force needed to hold the mold closed during injection. If […]

The Plastic Forming & Manufacturing Process: Top 7 Techniques

But although they’re found everywhere, not everyone knows just how they came to be. In fact, in the world of manufacturing there are eight different plastic forming methods. Each is used for a special reason, although they can sometimes be used in combination to make more complex finished parts. Today, we will take a closer […]