Plastic Injection Molding Surface Finish: Making and Measuring Textures For Injection Molding

All plastic injection molded parts have a surface texture created by the tools that made them. To get the surface finish and texture that you want from injection molding, it’s important for you to learn how we make and measure such finishes in our inspection department. At Star Rapid, we follow the finishing standards of […]

How Gate Design Affects Your Plastic Parts

The runner and gate system used in plastic injection molding is responsible for directing molten plastic from the nozzle of the molding machine into the cavity of the tool. The gate architecture and its location affects cycle times, tooling costs, lead times, the location of witness marks and many other potential defects that are commonplace […]

Conformal Cooling for Plastic Injection Molding

Conformal cooling for plastic injection molding is emerging as a technology that could offer some great advantages for making mold tools. Because of this, our team at Star Rapid has been investing in research and development to provide this service in the future. Using advanced manufacturing techniques like metal 3D printing will make this solution […]

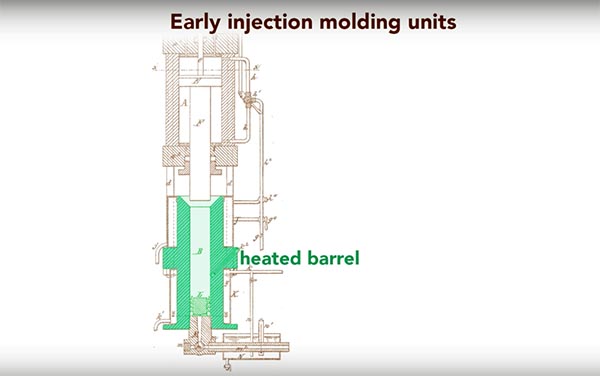

The Importance Of The Reciprocating Screw In An Injection Molding Machine

The single greatest innovation in the 20th century for improving plastic injection molding comes from one of history’s original and most basic machine types: the screw. Let’s take a closer look at the ingenious application of this simple design and how it improves the plastic injection molding process. How Was Plastic First Injected? Prior to […]

Choose The Right Plastic For Your Next Project

With thousands of plastics on the market, it can be a daunting task to decide which type is the best for your next rapid prototyping or low-volume manufacturing project. When choosing which plastic to use, there are going to be trade-offs between cost, moldability, surface finish, durability, strength and many others. The choice of plastic depends on […]

Gordon Styles Featured in MakePartsFast Podcast

Last week our founder and president Gordon Styles was a guest on Leslie Langnau’s MakePartsFast podcast. In the interview he discussed designing for plastic injection molding as well as 3D printed conformal cooling cores.

Portuguese

Portuguese French

French