- Case Studies

- Cash’s Case Study: Manufacturing Beer Bottle Brackets

Cash’s Case Study: Manufacturing Beer Bottle Brackets

- Star Rapid

- 6 min

- Case Studies

- Cash's Case Study

Cash’s Case Study: Manufacturing Beer Bottle Brackets

- Star Rapid

- 6 min

Company

CASH'S Awards and Promotion Solutions

ABOUT

Australian Memorabilia and Promotional Items Designer

Industry

Consumer Products

Components

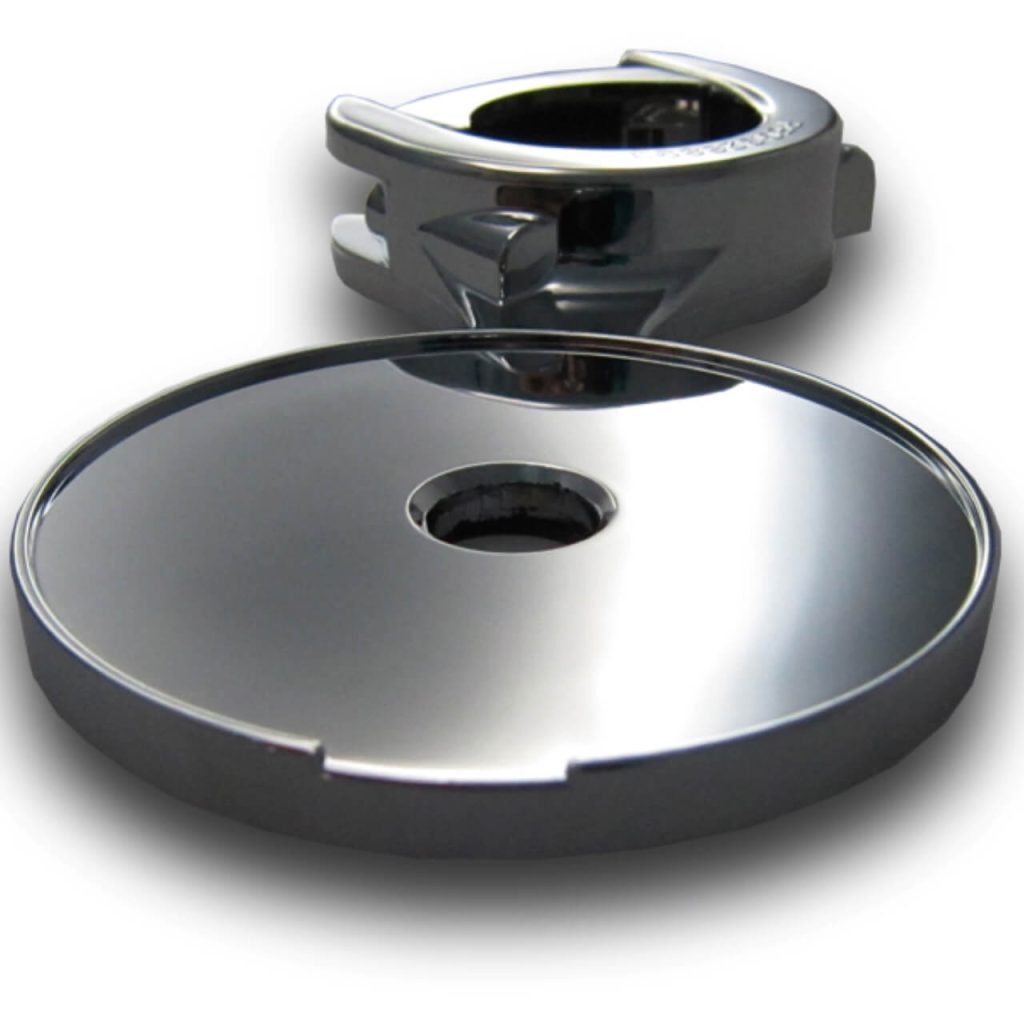

Custom Bottle Hanging Brackets

Mold Material

NAK80

Parts Material

ABS

Quantity

30,000 Units

Lead time

30 Days

Services

Table of Contents

Table of Contents

“Star delivered these parts quickly and professionally. The prototypes met the high standard I demand from any supplier and are currently being fine-tuned before the applications for patent are submitted.”

Buyer, Primary Fluids Inc.

Building a Better Beer Bottle Bracket

When you’re in the business of memorabilia, promotional gifts, and keepsakes, you need to create unique and attractive items. Cash’s of Australia specializes in such products and urgently needed thousands of units of their new bottle hanging brackets ready for the market. Not all manufacturers can meet this demand, but Star Rapid quickly created the necessary tools and parts to ensure the commercial launch in Australia.

The Challenge: Ensuring Fast and Efficient Production

We reviewed the client’s main requests and needs, and we found that not only did this project have a short lead time, but it needed to be done inexpensively with shiny finished plastic parts that looked like metal.

Our Approach: Clear Communication & World Class Equipment

Our plan to get this done included:

- Partnership and direct communication

- Design for Manufacturing (DFM) review

- Use of modern equipment

Establishing Clear Communication

We kept direct contact with Cash’s teams to discuss adjustments, material selection, and manufacturing methods, which was crucial to giving the client a clear view of the order’s progress.

Conducting the DFM Review

Design for Manufacturing (DFM) is the review of the client’s design files, and it’s a crucial step to identify the best manufacturing methods, make production as efficient as possible, and improve the part’s quality. During the DFM, we were able to make minor modifications to the CAD files sent.

Using the Best Equipment for the Job

Ultimately, producing high-quality parts in such a short time requires advanced equipment. We use imported advanced CNC machines, world-class cutting tools, and modern process control software programs.

We found CNC machining to be the most efficient solution for making the mold tools, while plastic injection molding is the best alternative for producing a high volume of parts in a relatively short time.

Our Production Strategy: Making Plastic Look Like Metal

Our production strategy started with material selection and identification, followed by toolmaking, injection molding, and finally chrome plating, inspection and delivery.

Selecting Materials

The right material selection is critical. For toolmaking, it was necessary to use a steel that accepted polishing well to produce the necessary shiny finish. We chose NAK80.

This Japanese steel is commonly used to make tools that require transparency and high gloss. It doesn’t require heat treatments, has good wear resistance, and, most importantly, has exceptional polishability.

The holders were made of ABS plastic—a highly durable material, resistant to impact, that can withstand temperature variations and accepts various types of surface finishes well. It’s ideal for building visually appealing products.

All incoming raw materials for the project underwent Positive Material Identification (PMI) to confirm their conformance to specifications.

Samples were sent to our inspection department and evaluated using modern measurement equipment in a controlled environment. We performed several analyses and compared them with a precisely calibrated database to be sure the materials would perform adequately during moldmaking and plastic injection. It helps our clients know they’ll receive the highest quality products.

Watch this video to see how the process is typically conducted in plastics.

And here is how the PMI of metals is done at Star Rapid.

Moldmaking

We primarily made the molds using CNC machining. That meant creating a cutting program and selecting the most appropriate speed, feed rate, and cutting tools. Next, we coded the machines using a specific programming language that controlled each action of the equipment. Finally, we set up the machines, monitored production, and adjusted the cutting program as needed.

One of the many advantages of using CNC machines to make molds is the ability to modify them as necessary, and our operators are experts in creating and editing G-Code.

After machining, the parts underwent a meticulous polishing process to remove burrs and machine marks and to create the design’s high mirror finish. We carefully hand and machine-polished the cavity side of the mold, which shapes the external features and outer side of the product.

Plastic Injection Molding

Some injection molded parts were produced as samples to test the tools. Then, it was time for production. During manufacturing, we followed these common steps of the injection molding method:

- Clamping the core and cavity in the machine

- Melting the ABS plastic to a complete liquid and injecting it into the mold

- Monitoring the temperature throughout the injection process

- Applying pressure directly to the mold to ensure the liquid fills every cavity

- Allowing the molds to cool so the plastic solidified

- Opening the mold and ejecting the final product

- Removing and trimming the waste material flush

Threaded brass inserts were added later, rather than drilling and threading directly into the plastic case.

Surface Finishing

We used chrome plating to create the metallic, mirror-like shine of the finished parts. First, we prepared and cleaned the parts before coating them with a base layer. Then, we immersed the parts in a chrome plating bath and finally rinsed and dried them to remove excess chemicals.

After surface finishing, the parts were inspected by our quality control department, where we analyzed profile, measurements, texture, and much more.

The Result: A Large Order Delivered in a Rush

We were able to deliver 30,000 units of the bottle holder to our client in four weeks. And every single one had an impeccable build and finish.

Cash can rest easy knowing that the end users who assemble promotional kits for their companies aren’t at risk of having their brands associated with inferior-quality products.

This delivery was possible because of:

- Project and manufacturing optimization from the start

- Advanced machinery to quickly create and trial the tools

- Skilled operators in CNC machining and plastic injection molding centers

- Quality control capable of easily inspecting high volumes

In projects with tight lead times, it is always important not to let haste interfere with standard processes that maintain quality. At Star Rapid, this is a must, and we take pride in the fact that no part leaves our factory before we are sure of its quality.

High-Quality Parts in Rapid Time

You deserve the same level of commitment to deadlines and quality for your products. Not every manufacturer can offer this, but Star Rapid has methods that ensure the best parts, every time.

We have modern facilities equipped with advanced measurement, production, and final inspection tools. Our engineering team has years of experience managing projects for various industries, and we excel in all the manufacturing processes needed to produce your parts from start to finish.

Submit your CAD files to get a free quote today, and let’s discuss a quicker and more affordable way to make your parts.