Manufacturing Tooling Design Fundamentals

There are many types of specialized tools used in manufacturing to make every imaginable kind of product, from shoes to submarines and everything in between. Because their variety and application are so broad, we’d like to focus our attention on forming tools, and we’ll explain how they differ from other tools found on the factory […]

Metal 3D Printing – How Does it Work?

What Is Metal 3D Printing? Metal 3D printing is a revolutionary technology that produces impossible-to-make parts directly from CAD data. Advantages to this process include the ability to produce strong, complex geometries, internal lattice structures, conformal cooling channels and other features that cannot be made with traditional machining. Parts can be made quickly with a […]

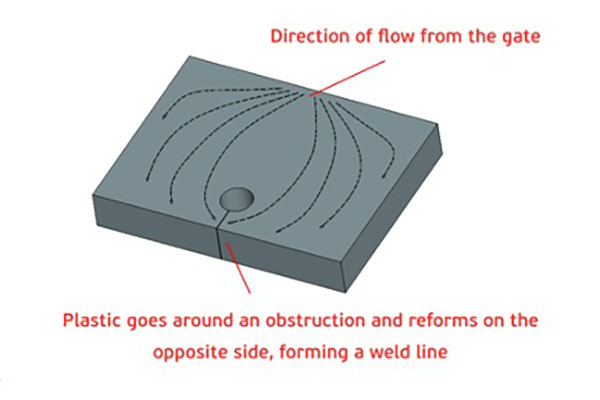

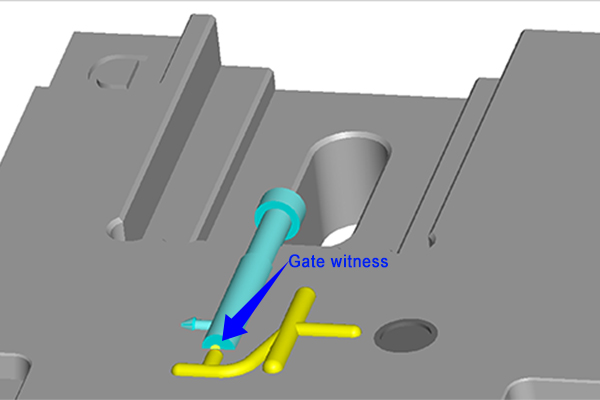

Molding Defects: The Top 5 Plastic Injection Molding Defects (and How to Solve Them)

Plastic injection molding is the most widely used mass-production process in modern manufacturing. It’s so popular because useful products of every conceivable size, shape and function can be made quickly and efficiently with reliable and repeatable performance. As versatile as it is, getting the best results from plastic injection molding still requires adhering to good […]

Micro Machines are a Big Win for Plastic Injection Molding

We’re excited to announce that we’ve expanded our capabilities in plastic injection molding with the recent addition of two new Babyplast horizontal micro molding machines. This demonstrates our commitment to providing the most agile manufacturing services for customers who need small, precision plastic parts. Let’s look more closely at the advantages of micro molding and […]

What Is A Coordinate Measuring Machine Used For?

One of the essential workhorses for product verification is our coordinate measuring machine. We use it every day to qualify rapid prototypes and production parts that have complex geometries with tight tolerances. Learn more about how this versatile machine is one more way we ensure every part we make meets and exceeds your expectations. What […]

The 10 Most Popular Injection Molding Materials

We often get asked what the best plastic injection molding resin is to use for certain projects. And honestly there is no one answer for that. The best resin is the one that works for you and your unique circumstances. The good news is that there are many thousands of plastic injection molding resins to […]

Portuguese

Portuguese French

French CHINESE (中文)

CHINESE (中文) German

German